OTC ROBOT Monitoring System Software

OTC ROBOT Monitoring System Software

OTC ROBOT Monitoring System Software

In recent years, Industry 4.0, artificial intelligence and machine networking have been topics that everyone has been discussing.

How can we use this information to collect data and manage equipment ?

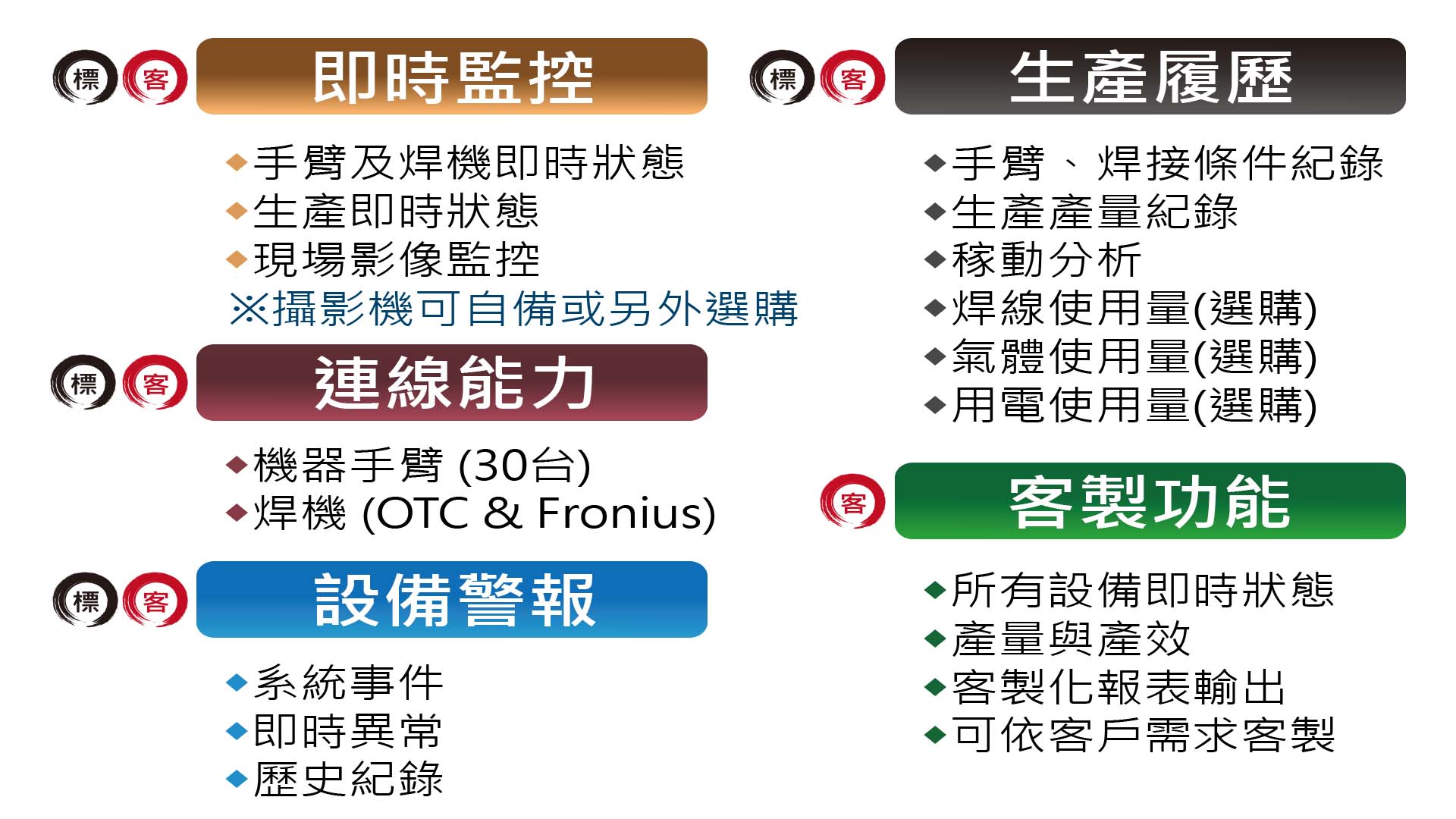

In order to effectively manage the aforementioned needs, our company has developed a production monitoring and management system that

can be combined with Japanese OTC automation robots.

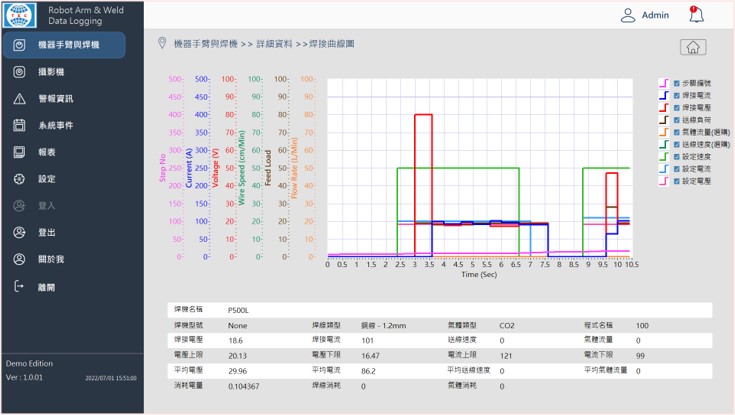

This system can effectively monitor the working status of robots and production processes on the production line, collect and analyze data in real time to optimize the production process,

Improve production efficiency and product quality. Through remote monitoring of the monitoring system, production defects can be discovered and corrected in a timely manner to ensure that products meet quality requirements.Reduce downtime and repair costs.

Through the monitoring system to record key data and parameters in the production process, the traceability and traceability of the production process can be realized, and the traceability and controllability of the production process can be improved.

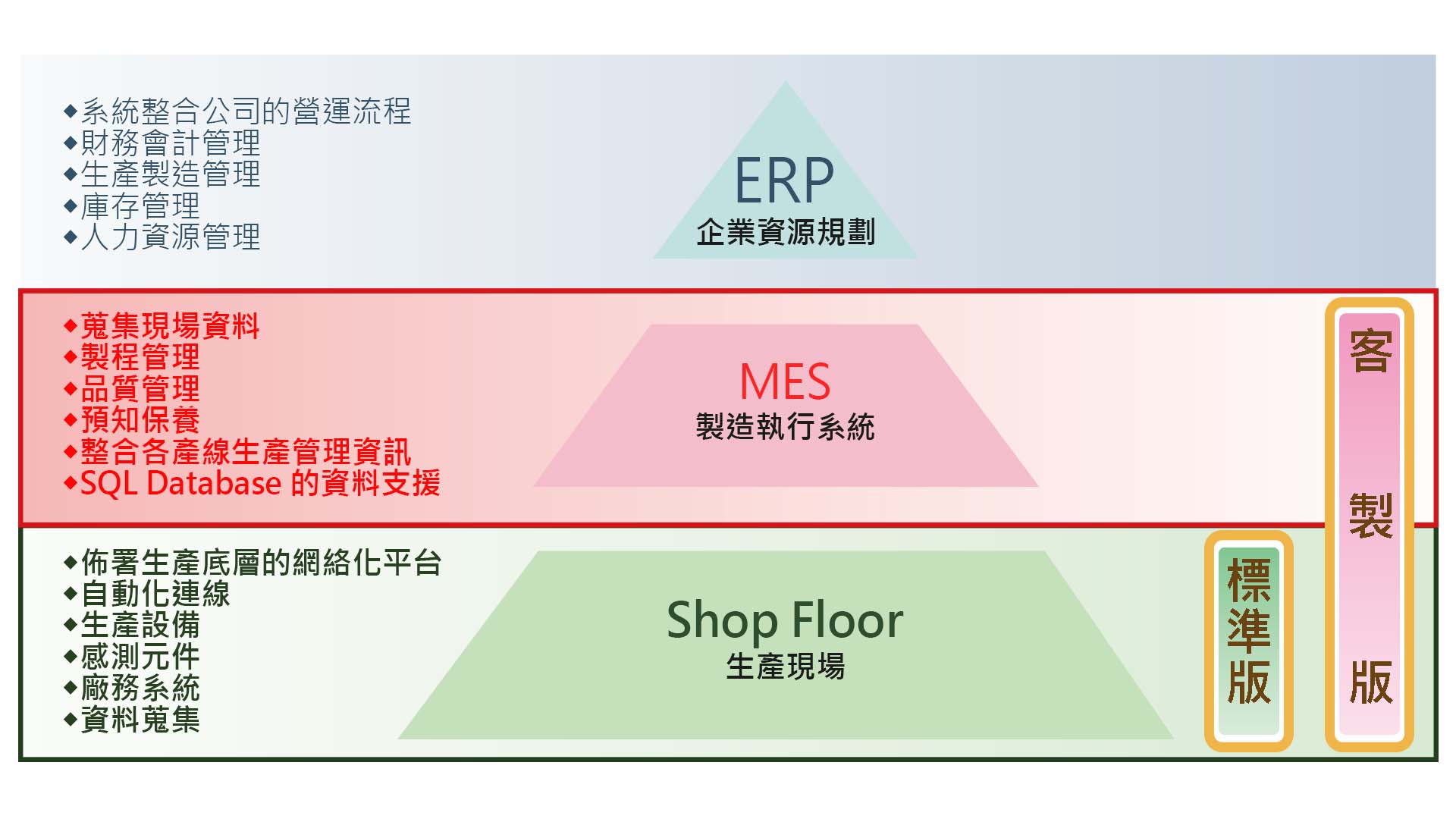

If ERP or MES systems are installed in the factory, our company can collect equipment information for effective management and analysis.

The monitoring system management system is divided into standard version and customized version.

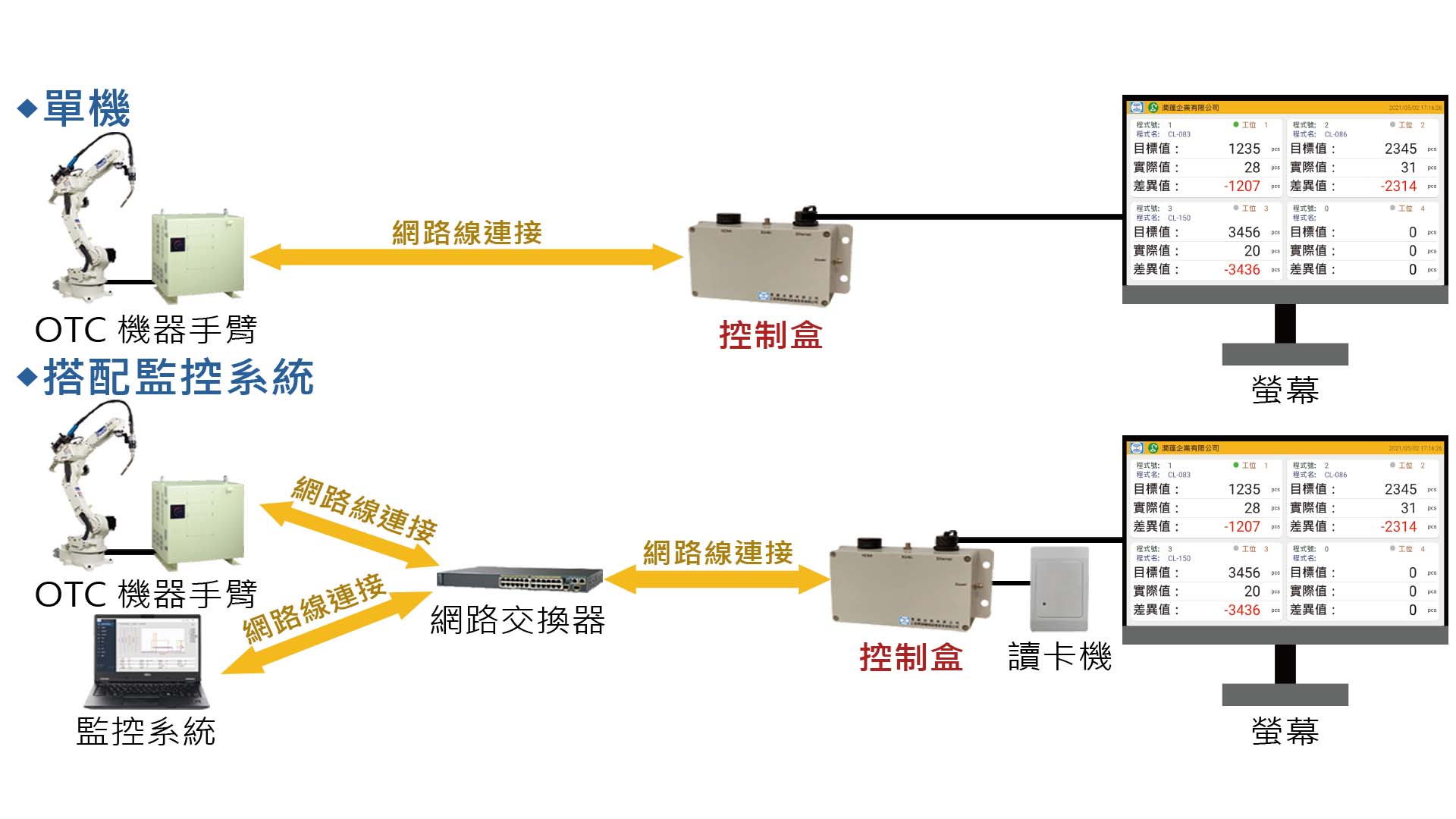

The so-called standard version of the monitoring system is mainly only for data collection in the OTC ROBOT on the production site.

In addition to the data collection of the OTC ROBOT, the customized version can also collect data for other equipment on the production site,

integrate production management information of each production line, and other customer needs. other needs.

You can also choose a Production Display Board Box with , so that you can check the production performance more efficiently.

(can correspond to multiple workstations)

For more information, please contact us

https://www.tec-robot.com.tw/contact/contact.html